Online Exporter Fully Welded Ball Valve - Expanding Through Conduit Gate Valve for API6A Standard – CEPAI

Online Exporter Fully Welded Ball Valve - Expanding Through Conduit Gate Valve for API6A Standard – CEPAI Detail:

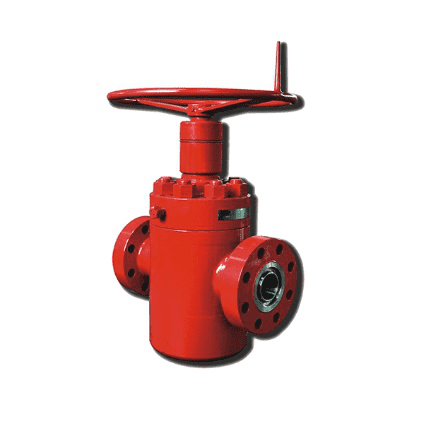

Expanding Gate Valve

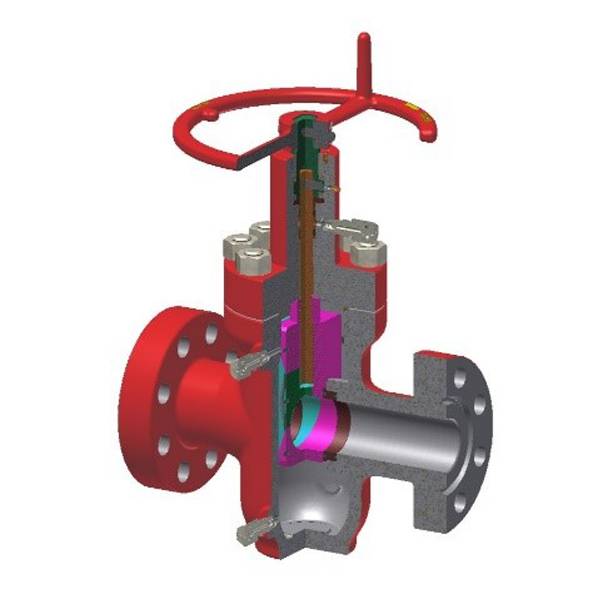

CEPAI’s WKM gate valve, full bore design, effectively eliminate the pressure drop and Vortex, slowing down flushing by solid particles in the fluid, valve gate with mechanical sealing structure, which does not require fluid pressure and good sealing performance, low torque operation during open and close operation, and low wear between valve gate and seat, metal to metal seal between valve bonnet and body, soft seal or metal to metal seal between valve gate and valve seat, inject sealant through injection valve periodically to improve the sealing performance of the valve

Moreover

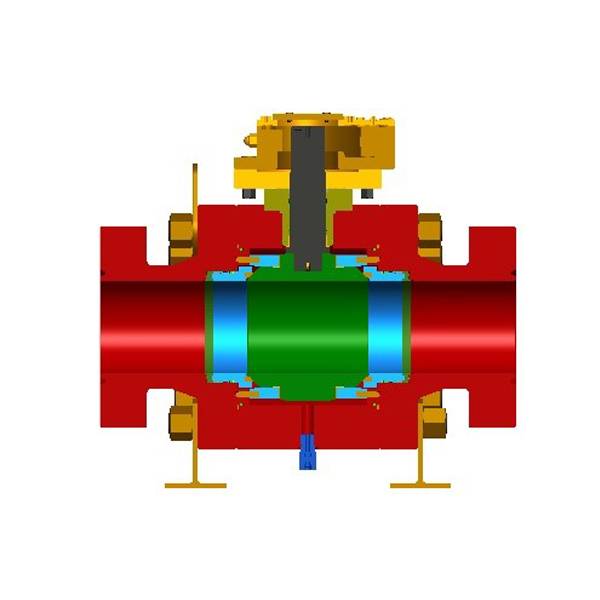

It’s expanding-style gates are used in Series NW and RWI Gate Valves. This popular gate design is used in manual valves to produce a high seating force against both the upstream and downstream seats simultaneously as the handwheel is tightened. This force effects a tight mechanical seal which is unaffected by line pressure fluctuations or vibration. The expanding gate allows a positive mechanical seal across both seats, both upstream and downstream, with or without line pressure. The gate assembly uses an angular gate face which is collapsed during travel. When closed, a body stop causes any further downward travel to force the faces of the gate assembly outward to affect a positive line flow seal. When opened, a bonnet stop causes any further upward travel to force bottom faces to expand and seal against the seats to isolate flow from the valve body cavity.

Design Specification:

Standard WKM gate valves are in accordance with API 6A 21th latest Edition, and use the right materials for different service according to NACE MR0175 standard.

Product Specification Level: PSL1 ~4 Material Class: AA~HH Performance Requirement: PR1-PR2 Temperature Class: LU

Product Features:

◆ Casting valve body

◆ Double Block-and-Bleed

◆ Repeated Positive shut-off

◆ External thermal body relief

Production Photos

Product detail pictures:

Related Product Guide:

Our target is always to satisfy our customers by offering golden support, superior value and high quality for Online Exporter Fully Welded Ball Valve - Expanding Through Conduit Gate Valve for API6A Standard – CEPAI , The product will supply to all over the world, such as: Eindhoven, Canada, Bhutan, We'd like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!