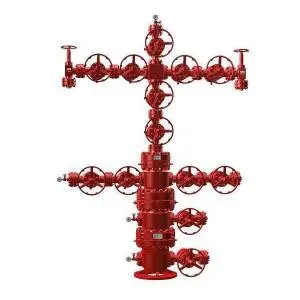

Oil wells are drilled into underground reservoirs to extract petroleum oil for commercial use. The top of an oil well is referred to as the wellhead, which is the point at which the well reaches the surface and oil can be pumped out. The wellhead includes various components such as the casing (the lining of the well), the blowout preventer (to control the flow of oil), and the Christmas tree (a network of valves and fittings used to regulate the flow of oil from the well).

The Christmas tree is an important component of an oil well as it controls the flow of oil from the well and helps to maintain the pressure within the reservoir. It is typically made of steel and includes valves, spools, and fittings that are used to regulate the flow of oil, adjust pressure, and monitor the well's performance. The Christmas tree is also equipped with safety features, such as emergency shut-off valves, which can be used to stop the flow of oil in the event of an emergency.The design and configuration of a Christmas tree can vary depending on the specific requirements of the well and the reservoir. For example, a Christmas tree for an offshore well may be designed differently from one for a land-based well. Additionally, the Christmas tree may be equipped with technology such as automation and remote monitoring systems, which allow for more efficient and safer operations.

The drilling process for an oil well involves several stages, including site preparation, drilling the well, casing and cementing, and completing the well.Site preparation involves clearing the area and constructing the necessary infrastructure, such as roads and drilling pads, to support the drilling operation.

Drilling the well involves using a drilling rig to bore into the ground and reach the oil-bearing formation. A drill bit is attached to the end of the drill string, which is rotated to create the hole. Drilling fluid, also known as mud, is circulated down the drill string and back up the annulus (the space between the drill pipe and the wall of the wellbore) to cool and lubricate the drill bit, remove cuttings, and maintain pressure in the wellbore.Once the well has been drilled to the desired depth, casing and cementing are performed. Casing is a steel pipe that is placed into the wellbore to reinforce it and prevent the collapse of the hole. Cement is then pumped into the annulus between the casing and the wellbore to prevent the flow of fluids and gas between the different formations.

The final stage of drilling an oil well is completing the well, which involves installing the necessary production equipment, such as the Christmas tree, and connecting the well to the production facilities. The well is then ready to produce oil and gas.

These are the basic steps involved in drilling an oil well, but the process can be more complex and sophisticated depending on the specific conditions of the reservoir and the well.

In summary, the Christmas tree is a critical component of an oil well and plays a vital role in the extraction and transportation of petroleum oil.

Post time: Feb-07-2023