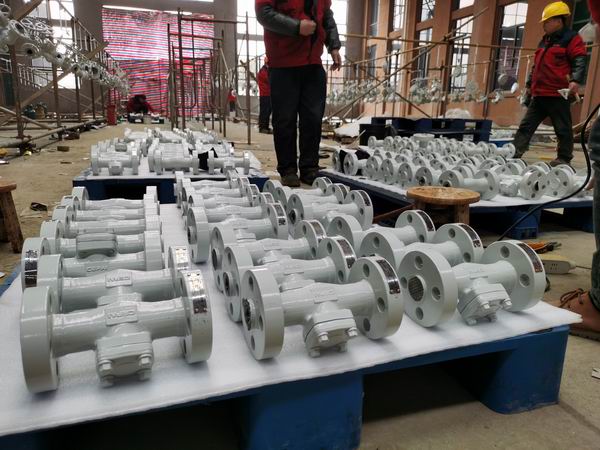

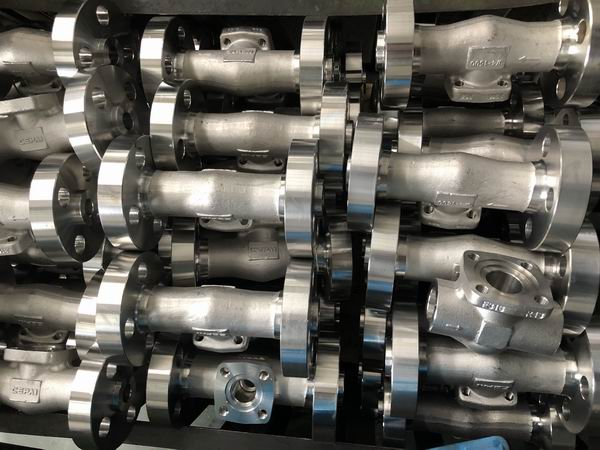

Forged steel lift check valve

●Standard:

Design: BS 5352, ANSI B16.34

F To F: ASME B16.10

Connection: ASME B16.5, B16.25, B16.11, B1.20.1

Test: API 598, BS 6755

●Forged Piston Check Valve Products Range:

Size: 1/2"~4"

Rating: Class 150~2500

Body Materials: Carbon Steel, Stainless Steel, Duplex Steel,Alloy

Connection: RF, RTJ, BW,SW, NPT

Tempertature: -196~650℃

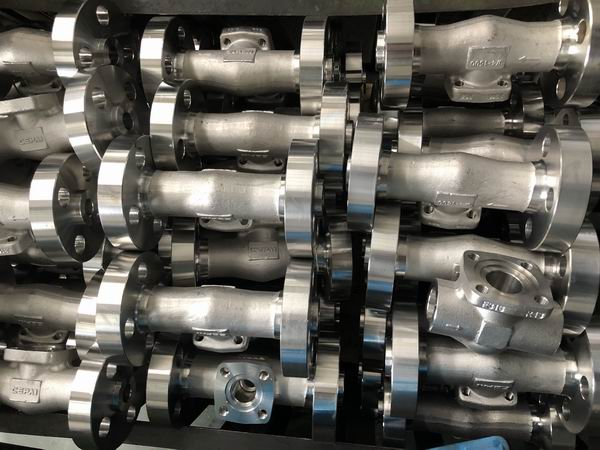

●Forged Piston Check Valve Construction and Function

● Full Port & Standard Port Design

● Bolt Cover

● Internally Assembled Hinge Pin

● Intergal Seat

For The Forged Piston Check Valve produced by CEPAI, the Valve seat is generally integrated or cemented carbide is surmounted on the body before direct processing of the Valve seat.

● Body and Cover connection & Gasket

For theForged Piston Check Valve produced by CEPAI, the valve body and bonnet can be connected as bolt connection, welding connection, pressure self sealing connection and other different structures, etc.

●Forged Piston Check Valve Main Parts & Material List

Body/Bonnet A105N,LF2,F11,F22,F304,F316,F51,F53,F55,N08825,N06625;

Disc A105N,LF2,F11,F22,F304,F316,F51,F53,F55,N08825,N06625;

Pin F6,F304,F316,F51,F53,F55,N08825,N06625;

Gasket SS+Graphite,PTFE;

Bolt/Nut B7/2H,B7M/2HM,B8M/8B,L7/4,L7M/4M;

●Forged Piston Check Valve

Forged Piston Check Valve produced by CEPAI is mainly used to block or connect the medium in the pipeline. Choose Forged Piston Check Valve of different materials can be used for water, steam, oil, liquefied gas, natural gas, gas, nitric acid,carbamide and other medium.