Factory wholesale 200mm Gate Valve - Casing Heads – CEPAI

Factory wholesale 200mm Gate Valve - Casing Heads – CEPAI Detail:

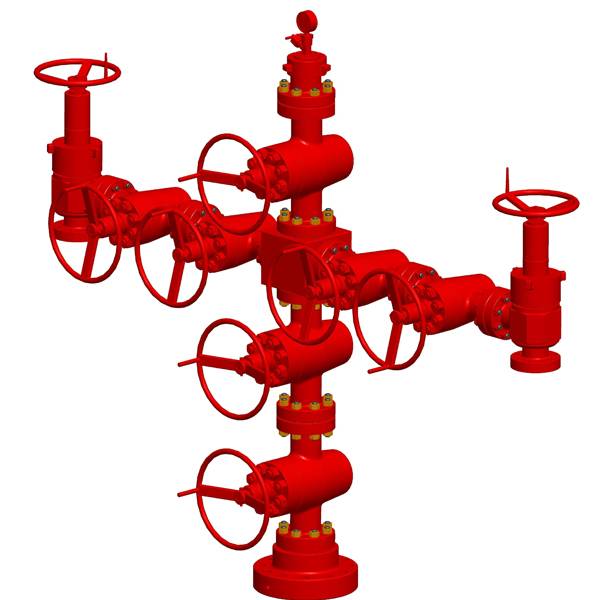

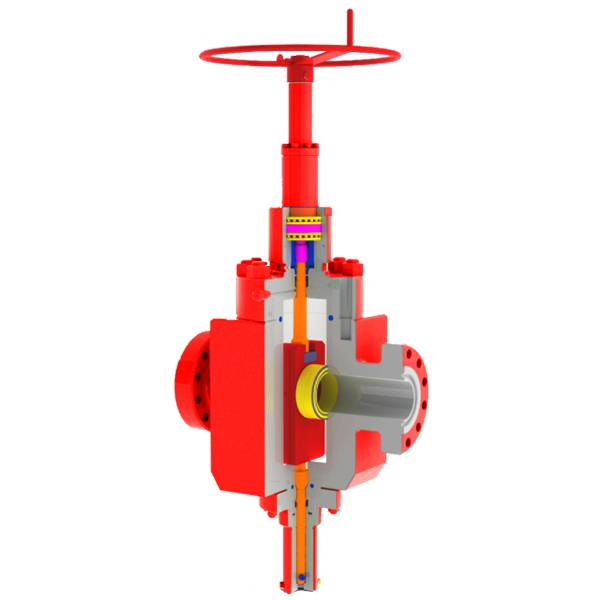

CEPAI manufactures tubing/casing heads, hangers and adapter Flanges in all sizes and pressure ratings. The casing head is the lowest part of the wellhead assembly and is always connected to the surface casing string. It supports subsequent drilling wellhead and completion equipment. Popular Adapter Flanges are double studded Adapter Flanges, Companion Flanges, and X Union Adapters. Customers may use Adapter Flanges for transition in nominal size and /or pressure rating. The Adapter Flanges have minimum overall heights, or customer specified thickness, consistent with design considerations. Tree caps are installed on top of Christmas Trees for quick access to the tubing bore-via Tester of Lubricator Adapter for bottom hole testing, installing back-pressure valves etc. Bottom Hole Test Adapters allow a flexible means of entry into the tubing bore. Bottom Hole Test Adapters are used where an integral flanged unit is preferred. These adapters are furnished in various sizes, and working pressure up to 20,000PSI.

Design Specification:

Standard Accessories are in accordance with API 6A 21th latest Edition, and use the right materials for different operating condition according to NACE MR0175 standard.

Product Specification Level: PSL1 ~4 Material Class: AA~HH Performance Requirement: PR1-PR2 Temperature Class: LU

Product Features:

◆ C-22 accepts C-21 non-automatic sealing casing hanger w/ type H seal ring, C-22 & C-122 automatic sealing casing hanger.

◆ C-22-BP-ET has bowl-protector lockdown screws in the top flange.

◆ C-22 eliminates the need for lockdown screws to retain bowl protectors.

◆ Bottom preparation can be either male-threaded, female-threaded,

◆ Supports blowout preventers while hole is drilled for next casing string.

◆ Provides for suspending and packing off the next casing string.

◆ Provides outlets for annular access.

◆ Provides for testing BOPs while drilling.

◆ Straight bowl prevents wedge-locking of bowl protectors, casing hangers and test plugs.

◆ Seal bore less likely to be damaged during drilling.

◆ Detachable base plate available for C-22 heads provides time savings

and adds value due to better utilization of customer-owned property.

◆ C-22-EG reduces number of leak paths, lowers cost and increases safety

as there is no need to work beneath the BOPs.

| Name | TUBING/CASING HEAD/HANGERS/ADAPTER/GOATS/FLANGE/CROSS/TEE |

| Model | ACCESSORIES |

| Pressure | 2000PSI~20000PSI |

| Diameter | 1-1/16”~13-5/8” |

| Working Temperature | -46℃~121℃(LU Grade) |

| Material Level | AA、BB、CC、DD、EE、FF、HH |

| Specification Level | PSL1~4 |

| Performance Level | PR1~2 |

Technical Data of Companion Flange.

|

COMPANION FLANGE |

|||||

|

Flange Size(ID) |

Casing Size |

WP |

Flange Size(ID) |

Casing Size |

WP |

|

11″ |

5 1/2″ OD |

2,000 |

11″ |

7 5/8″ OD |

5,000 |

|

11″ |

5 1/2″ OD |

3,000 |

13 5/8″ |

8 5/8″ OD |

2,000 |

|

11″ |

5 1/2″ OD |

5,000 |

13 5/8″ |

8 5/8″ OD |

3,000 |

|

11″ |

7″ OD |

2,000 |

13 5/8″ |

8 5/8″ OD |

5,000 |

|

11″ |

7″ OD |

3,000 |

13 5/8″ |

9 5/8″ OD |

2,000 |

|

11″ |

7″ OD |

5,000 |

13 5/8″ |

9 5/8″ OD |

3,000 |

|

11″ |

7 5/8″ OD |

2,000 |

13 5/8″ |

9 5/8″ OD |

5,000 |

|

11″ |

7 5/8″ OD |

3,000 |

11″ |

9 5/8″ OD |

10,000 |

Technical Data of Double Studded Adapter Flange

|

DOUBLE STUDDED ADAPTER FLANGE |

|||

|

Description |

Flange thickness(mm) |

Description |

Flange thickness(mm) |

|

2-1/16″x5M To 3-1/8″x5M |

70 |

11″x15M To 18-3/4″x15M |

256 |

|

2-1/16″x10M To 4-1/8″x10M |

80 |

11″x5M To 13-5/8″x5M |

144 |

|

3-1/16″x10M To 4-1/8″x10M |

130 |

13-5/8″x10M To 11″x10M |

267 |

|

3-1/16″x10M To 4-1/8″x10M |

80 |

13-5/8″x3M To 16-3/4″x2M |

150 |

|

4-1/16″x5M To 2-1/16″x5M |

75 |

13-5/8″x19M To 18-3/4″x15M |

256 |

|

4-1/16″x5M To 3-1/8″x5M |

83 |

13-5/8″x5M To 18-3/4″x15M |

256 |

|

4-1/16″x2M To 4-1/16″x5M |

80 |

18-3/4″x15M To 20-3/4″x3M |

270 |

|

7-1/16″x10M To 13-5/8″x10M |

170 |

20-3/4″x3M To 18-3/4″x15M |

256 |

|

7-1/16″x5M To 13-5/8″x5M |

150 |

21-1/4″x2M To 18-3/4″x15M |

256 |

More Features:

|

Material |

Application |

Body, Bonnet, End, |

Pressure Controlling Parts, Stems, Mandrel Hangers |

|

AA |

General Service |

Carbon/Alloy Steel |

Carbon/Alloy Steel |

|

BB |

General Service |

Carbon/Alloy Steel |

Stainless Steel |

|

CC |

General Service |

Stainless Steel |

Stainless Steel |

|

DD |

Sour Service |

Carbon/Alloy Steel |

Carbon/Alloy Steel |

|

EE |

Sour Service |

Carbon/Alloy Steel |

Stainless Steel |

|

FE |

Sour Service |

Stainless Steel |

Stainless Steel |

|

HH |

Sour Service |

CRA’s |

CRA”s |

Production Photos

Product detail pictures:

Related Product Guide:

We can constantly satisfy our respected customers with our good high quality, good price tag and good support due to we have been additional specialist and extra hard-working and do it in cost-effective way for Factory wholesale 200mm Gate Valve - Casing Heads – CEPAI , The product will supply to all over the world, such as: South Africa, Afghanistan, Singapore, We warmly welcome you to come to visit us personally. We hope to establish a long-term friendship based on equality and mutual benefit. If you want to get in touch with us, please do not hesitate to call. We will be your best choice.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.